Our mission is to uphold the delicate balance of People, Planet, and Profit, which are the three fundamental pillars of corporate sustainability. We aim to achieve this by:

SustainabilityOrganic & Recycled Raw Material, Health & Safety Of All, Dyes & Chemicals & Girl Child Education.

The program selects girls based on multiple criteria including enrollment in schools, family income, parent’s educational background, social background and the child’s aptitude. A comprehensive sponsorship is created to take care of a range of their educational requirements, providing not only academic support that enables them to make a success of their schooling experience but also material support. This includes uniforms, school bags, shoes, socks etc. to enable the girl child to go to school with dignity.

- Utilizing organic and recycled raw materials in our operations.

- Ensuring the health and safety of all individuals involved in our processes.

- Practicing responsible water usage to minimize our impact on the environment.

- Using only GOTS-approved dyes and chemicals that are safe for both people and the planet.

- Prioritizing the education of the girl child, as we believe that education is key to achieving sustainable development.

Manufacture Production ProcessesSustainable Manufacturing set up.

With the state of the art infrastructure, 43+ years of manufacturing experience and commitment towards nature and society, Shingora tries its best to provide its customers a product made out of passion and love! 2.5 AQL inspection levels and 4 stage inspection process. With a 300 piece minimum requirement to any design customise.

Weaving

With 52 Dornier and Sulzer rapier and air-jet jacquards and dobby machines, can weave 280,000 meters a month.

Yarn & Fabric dyeing

Great flexibility to yarn dye 1 kg to 200 kg lots. Can fabric and ombre dye sheer and light weight fabric.

Printing

An infrastructure of 4 Gali tables, a 10 screen Flatbed and an 18 head Digital printing machine combined with 25 years of experience printing gives us the ability to print on any textile material.

Finishing

The complex set of 15 different finishing machines gives us the ability to perform a range of finishes.

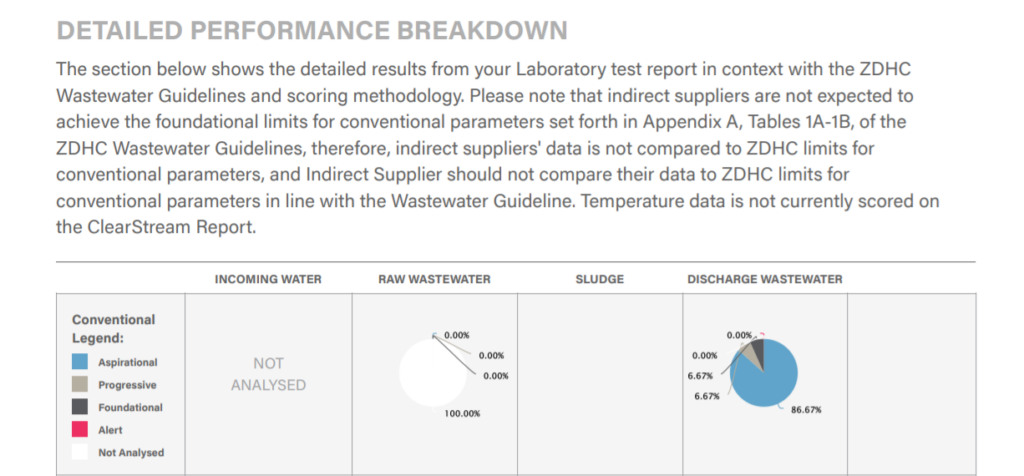

Commitment to ZDHC

At Shingora, we are committed to reducing our chemical footprint and protecting the planet. We have partnered with ZDHC (Zero Discharge of Hazardous Chemicals) and are actively working towards their goals. Our GTW (Green to Wear) audit assesses our environmental and energy management, greenhouse gas emissions, water and waste management, and chemical management practices. In addition, our CTW (Clear to Wear) program ensures that we monitor the non-usage of hazardous chemicals and maintain product traceability.

Our 2022 Higg FEM Verified score was 73.7% which is a testament to our commitment to sustainability. We are also eager to collaborate with our customers on new sustainable packaging ideas. We take pride in our responsible water management practices, which involve reusing over 40% of water in our production processes and horticulture. The remaining treated water is redirected to a tree plantation adjacent to our facility, where we use a unique technique to evaporate water through the leaves of Casuarina trees. By doing so, we can maintain a balance between our production needs and environmental conservation.

Environmental and Safety Certifications

By collaborating with our network of partners and customers, we want to ensure that our action will have a positive impact on our environment and on people’s lives, in order to preserve a world worth living in.

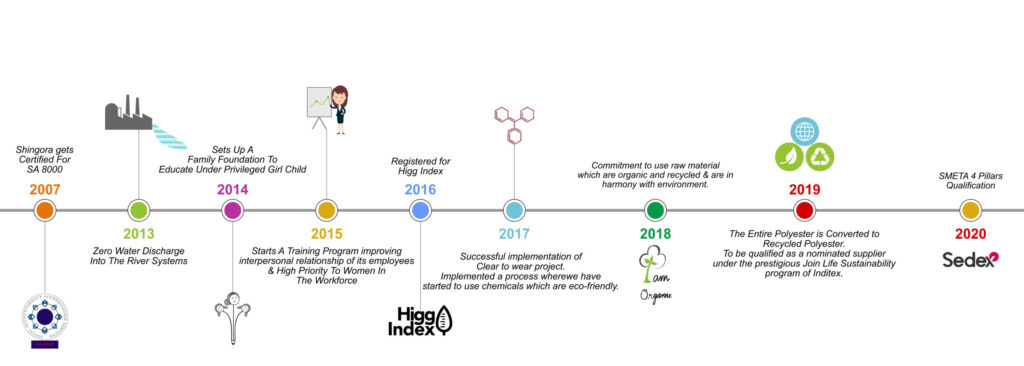

Sustainability Timeline

Upon contact, we will allocate a merchandiser who will work with you to understand your requirements, assist you to narrow down on design and fabric selection and convert your ideas into reality.

PartnersPartners who trust